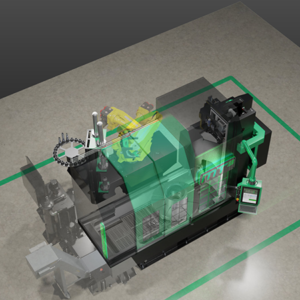

The new MT³ by Bourn & Koch. A vertical grinder capable of much more. MT³ is short for moving table modular technology machine tool. This vertical grinder is built off of the Blanchard 22AD-42 platform, utilizing the core components of the machine with a unique interchangeable spindle system to allow for the machine to be fully tailored to your production requirements and maximum flexibility as they evolve and change.

MT³ is a CNC vertical grinder designed to be more than just a replacement for your Springfield vertical grinding machine. Learn more about what MT³ is capable of by checking out this video. With over 40 years machine tool building experience and 2500 years of combined American Machine Tool engineering in our archives, the MT³ is a vertical grinder designed, engineered and built with precision in mind. Based off of the tried and true platform of the Blanchard grinder, the machine is capable of multiple operations such as milling, drilling, tapping, and turning.

The machine’s spindle can be swapped out, either manually or via our innovative robot cell, to allow for you tailor the right spindle and tool for your job. Vertical grinding is a niche in manufacturing. Having the ability to utilize the machine for milling and turning will keep it busy even when you are not running it as a vertical grinder.

Each machine is provided with a Fanuc CNC control (model dependent on options chosen), linear ways and ball screws for for easily achieving high tolerances. Our conversational HMI guides the operator through the grinding process, reducing specialized training required to run the machine. Additional programming of functions can be accomplished via CAM software or via M & G code programming. Each MT³ is a quality CNC machine tool crafted by precision machine tool builders with decades of experience.

MT³ Vertical Grinder Construction:

- The base is constructed of heavy-duty, stress-relieved steel weldment with intelligently applied concrete polymer for additional dampening and to eliminate vibration.

- The column is a heavy duty, stress-relieved steel weldment with intelligently applied concrete polymer for additional dampening and to eliminate vibration. The column supports the spindle head over the full rated length of travel.

- The table is positioned by a precision servo-cylinder assembly. The table is equipped with both rapid traverse and feed in either direction.

- Precision way areas are provided in the column and base for mounting the spindle head and table on hardened and ground, preloaded, precision linear roller guide ways.

- The work spindle is a self-contained unit mounted on precision bearings capable of up to 200 RPM (optional).